Your workflow

- Your challenge

- Our solution

Panel building with 2D schematics

- Where exactly are the components placed in the control cabinet? Does it all fit?

- No information about where cable ducts or bore holes should be placed

- Assembly and cabling can only be realized by experienced employees

- Every finished control cabinet looks different, despite being produced in series

⇒ Questions, re-work and a lack of personnel waste both time and precious resources

Panel building with a 3D model

- All components are already positioned on the mounting plate and displayed realistically

- The entire structure of the control cabinet is clearly described

- Understandable visualizations for coordination and project approvals

- Production assistance tools can guide even inexperienced workers through mounting and wiring

⇒ Virtual prototype for fast panel building and smooth approval processes

That's how our customers in panel building benefit from working with Eplan

- Ingela

- KBB

- Grübl

- Alexander Bürkle

"Error rates went immediately to zero, every length of wire length fits perfectly, and the control cabinet also looks much better."

Using Eplan Software to create the digital twin for your panel building

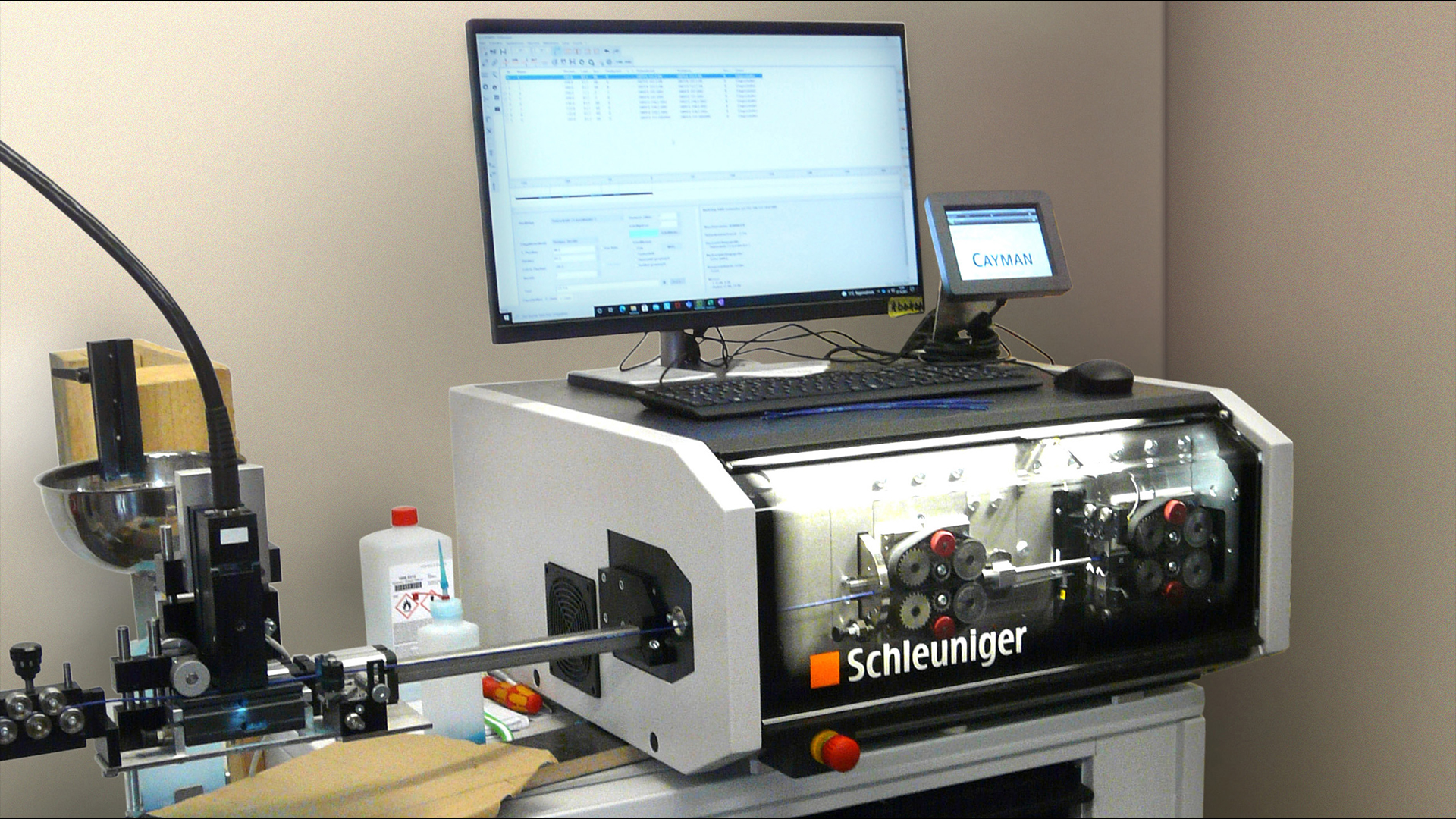

There’s still a lot to do after creating the schematics. Eplan provides you the software for the 3D designs of your control and switchgear systems. Eplan is also utilized on the production floor to simplify control cabinet manufacturing based on the digital twin.

- Machine building

- Digital twin in switchgear manufacturing